Our TPM approach

We understand TPM as Total Productive Management.

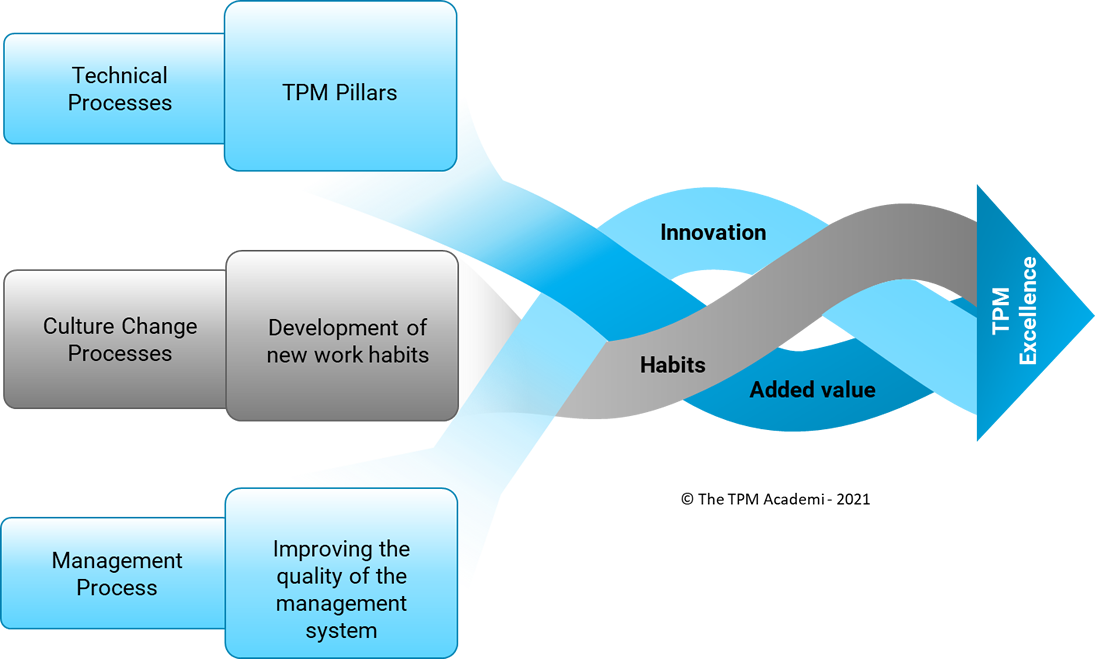

We understand the concept of Total Productive Management as an innovative industrial management system comprised of technical processes aimed at

optimizing the efficiency of production processes, cultural change processes that help create new behaviors conducive to productivity,

and management processes that enable the organization to operate more efficiently.

Our interpretation of the TPM concept goes beyond seeing it merely as a technical or maintenance model. Numerous companies with extensive TPM experience,

some of them certified with the TPM Award, assert that the scope of TPM should be corporate and should cover the entire value chain not only of

the company itself but also the extended chain integrated by suppliers, customers, and other associated companies, interconnected

in real-time thanks to the power of new technologies.

Integrated TPM system development

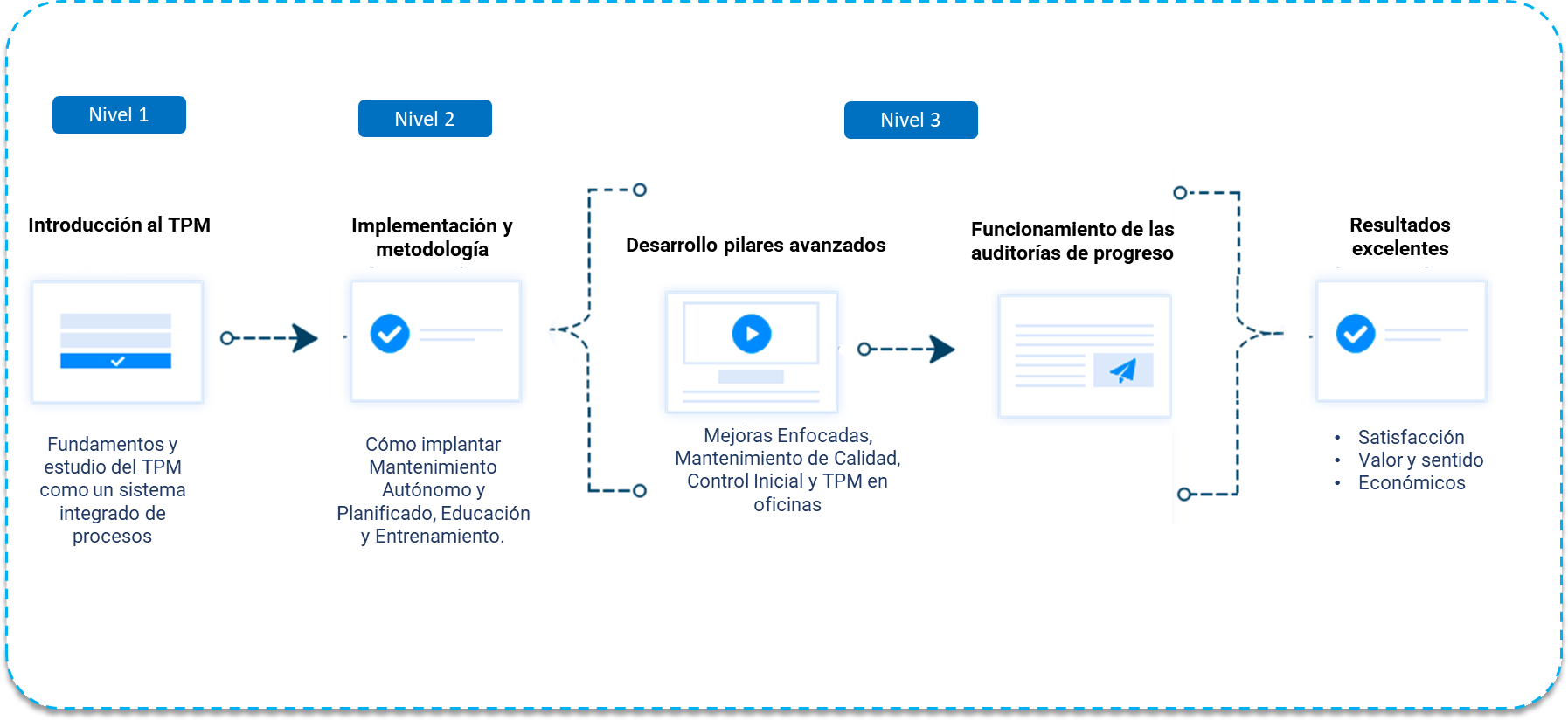

The implementation strategies of a TPM system with a comprehensive approach, involves the preparation and orderly development of the three processes that make up the system. The methodology of the TPM pillars has, since its inception, been structured in progressive and cumulative steps. This approach can be transferred to the processes of cultural change and improvement of management methods.

Working in steps allows to advance in a safe way, provides satisfaction for the partial achievements reached that stimulate to continue with its development. The standardized methodology in steps facilitates its application and management throughout the organization.

It is also necessary to consider the design of an organization that facilitates the participation of all areas of the company in the development of the project, as well as to have a structure of coordination and global leadership of the project.

TPM development at the shopfloor

One of the essential features of TPM operation is the development of small work teams at the operating levels. TPM work in the shopfloor goes beyond transferring some light maintenance tasks to the operators. These small teams must have the ability to work with autonomy, and their daily activities cover the initiatives considered in all TPM pillars.

Scop

The online training programs we offer have been designed to facilitate the orderly implementation process of TPM. They present the fundamentals and principles, but most importantly, they focus on how to implement and manage the different actions that make up the core processes. We provide alternatives regarding the decisions factory leaders must make when planning and developing a TPM project.

© 2023 The TPM Academy is a strategic unit of Apsoluti Business LTD.